INGREDIENTS & RECIPES

Try one of our peer reviewed recipes and ingredient kits! Each of these recipes are designed and hand crafted by the staff at KJ.

All kits include the required ingredients and instructions.

Try one of our peer reviewed recipes and ingredient kits! Each of these recipes are designed and hand crafted by the staff at KJ.

All kits include the required ingredients and instructions.

EQUIPMENT

Starter kits are a great way to get started brewing. Our different kits have everything you need to get that first batch cooking.

Starter kits are a great way to get started brewing. Our different kits have everything you need to get that first batch cooking.

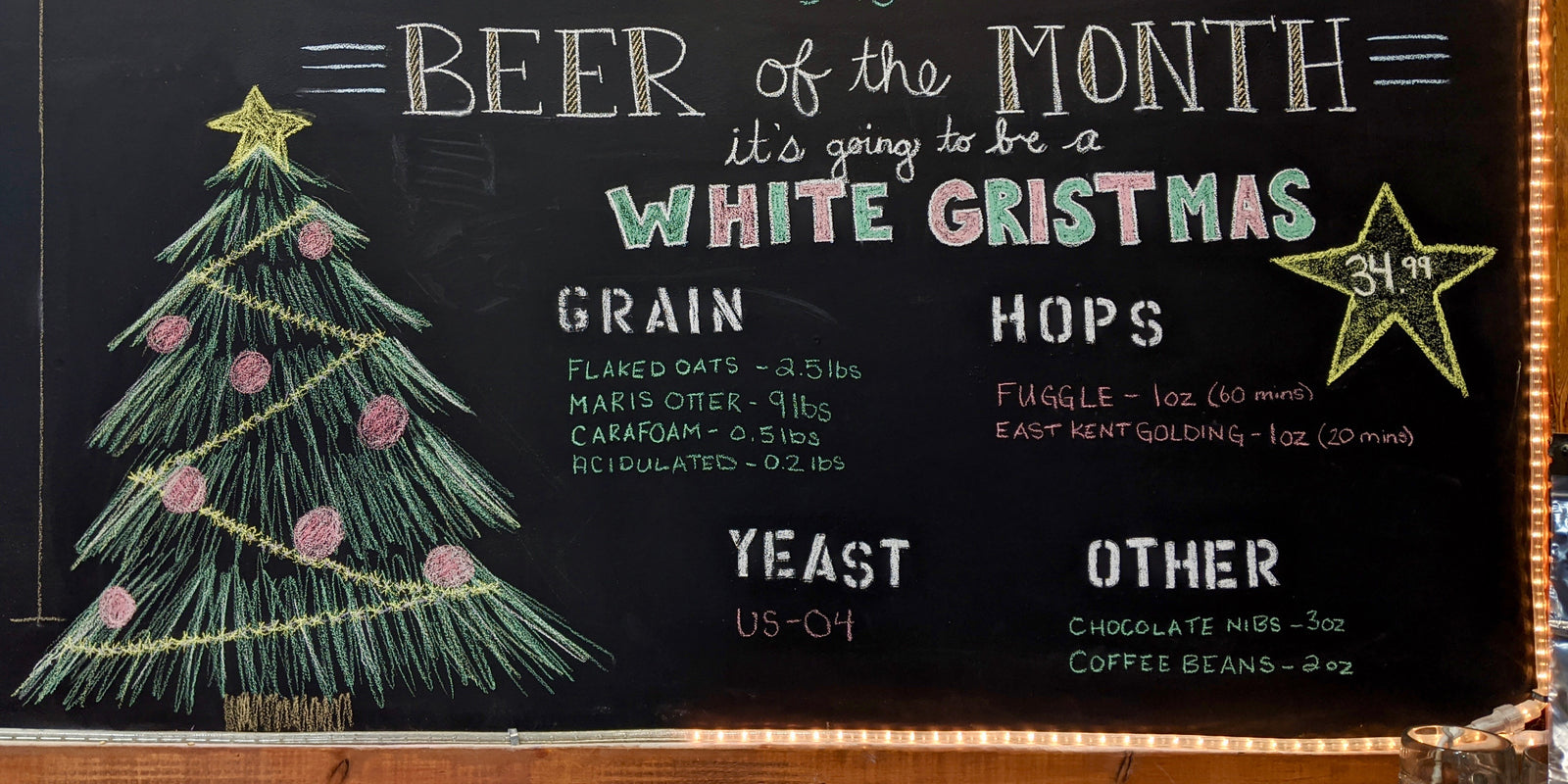

It's Going to Be a WHITE GRISTMAS

December 05, 2019 7 min read

Beer of the Month Program

December 2019 - White Gristmas - $42.99

One of the best parts about making beer (aside from drinking it) is the social aspect. Brewers love to swap recipes, discuss what well or horribly wrong in their brews. We thought it would be a fun idea to start a beer conversation here. We're going to make a beer every month here and encourage other brewers to make it as well. In the end, we're hoping we can share our opinions and experiences with the recipe and crowd-source some improvements. The recipes will be easy to make and we will gladly assist new home brewers in the production of these beers. They will all be 5.5 gallons in size. We find that after fermenting and racking a 5.5 gallon batch turns into a standard 5 gallon batch pretty quickly.

At the start of every month we will post the recipe in store, as well as on our website, Facebook, Instagram, and Twitter. We will also have a set price for the recipe that will include a discount of up to 25%!

White Gristmas

White Stout – 5.5 Gal - OG 1.066 – FG 1.018 – ABV 6.3% - IBU 24.3 – SRM 5

Purchase This Recipe Online

This beer is deceptive looking. From simply looking at it, it appears to be a simple gold coloured beer. You might think to yourself that this will be a light, crisp blonde ale – but you would be wrong. Close your eyes and take a sip; your brain will be convinced that this beer is dark stout. White Gristmas is a full bodied, thick tasting beer with STRONG notes of coffee and chocolate.

This beer is the brainchild of Devon. She tried a similar beer in Muskoka back in October and has been trying to mimic the deceivingly full-bodied beer since. The strong, stout like flavours are accomplished by a few special additions. First, adding lactose, as well as lots of oats and Carafoam creates a thickness and mouthfeel to the finished product. Next, to get the chocolate and coffee flavours stouts typically have without adding dark malts, we added coffee beans and cacao nibs to the fermenting beer. The beans and nibs give a bunch of flavour, without adding much of any colour to the finished beer. The end result is a deceptively full bodied, chocolate white/blonde stout!

Ingredients (All available at our shop)

Grains

- Maris Otter x 9.0lbs

- Flaked Oats x 2.5lbs

- Carafoam x 0.5lbs

- Acidulated Malt x .25lbs

- Lactose x 0.5lbs

Hops

- Fuggle (4.9% A.A.) - 1.0 oz @ 60 min

- East Kent Golding (5.9% A.A.) - 1.0 oz @ 20 min

Yeast

- S-04 English Ale Yeast x 11.5g sachet

Extras

- Cacao Nibs x 3oz (included in price)

- Coffee Beans x 2oz (not included in price)

- Irish Moss (1 tsp for last 15 minutes of boil)

- Dry Malt Extract (0.4 cup for priming at bottling)

Important Tips on Brewing

- Be extra cautious when it comes to cleaning! Once you have stopped boiling your wort everything that gets in contact with the beer MUST be sanitary.

- The temperature of your mash is ABSOLUTELY CRITICAL. Not being in the 150-155f range can drastically affect your beer. Make sure you correct the temperature ASAP once all of the grain has been added to the mash.

- Oxidization: Airspace is always something to consider. When undergoing primary fermentation airspace is needed so that the beer can bubble up and ferment vigoursley without leaking out of the container. The fermentation creates a layer of CO2 that remains in the pail due to the airlock. Once primary fermentation is over, and the lid has been opened, the layer of CO2 dissipates, and oxygen replaces it. At this point airspace can ruin your beer.

Step by step Instructions on the other side ààà

Instructions

Mashing -> converting the grain into a fermentable liquid.

- Bring 6 gallons of water in your brew pot to 155°F. This is our strike temperature. Turn off the heat to the pot.

- Wrap the muslin/nylon bag around the brew pot and slowly pour all the milled grains (EXCEPT the lactose, that is added during the boil) into the bag. Stir them in while adding to prevent clumps. The addition of grain should drop the temperature down to 150-153°F.

- We want to mash the grain at 154°F for 60 minutes. It is very important to hold the temperature at 154°F. If the temperature rises above 155°F it hurts the fermentation, or if it dips below 149°F it can lead to a thinner tasting beer.

- The first 15-30 minutes are essential for the success of your brew. The temperature HAS TO BE IN THE RANGE OF 150-155°F. Sometimes adding the grain to the strike water does not lower the temperature enough, in this case add a little bit of cold water to bring the temperature down. Cover the pot with your lid and let it sit.

- Most brew pots will be able to maintain 154°F without adding heat for 20 minutes, we recommend checking the temperature every 15 minutes, and if it drops add more heat to bring it up. We recommend opening the lid and using a thermometer in the liquid.

- After 60 minutes, bring the temperature of the mashing grain up to 170°F and hold for 10 minutes. This is our mash out.

- Time to remove the grain. Lift the bag full of grain out of the brew pot. Let the liquid in the bag dribble into your wort. Once that is done, put the bag inside of a brewing pail, or another empty pot. There will be about 4 gallons of wort in the brewpot, we need to get it to 6 gallons before we can begin the next stage.

- Run warm water through the grains in the bag, aim for 170°f – let it run through the grains and add to the brewpot. Add until you reach 6 gallons.

- PSA: It is natural to think that the grains need to be squeezed to get all of the liquid out of them, DO NOT DO THIS. Aggressively squeezing the grains will lead to tannin extraction and a doughy taste in your beer. Lightly pressing the bag is fine, but do not try to squeeze every last drop out.

Boiling -> Hop addition time

- Bring 6 gallons of your wort to a rolling boil, and let it boil for 5 minutes, this is called the hot break.

- Add 1oz of Fuggle hops to the pot and set a timer for 60 minutes, keep the wort boiling (212°f) and uncovered.

- With 20 minutes left in the timer add 1oz of East Kent Goldings, the Irish Moss, and if you’re using a wort chiller add that too. With 10 minutes left in the timer, add the half pound of lactose to the boil. Stir it in to make sure it dissolves.

- When your timer goes off, turn off the heat, and proceed to the cooling stage.

- Now it’s time to cool the beer down to 75°f (20-25°c) as quickly as possible.

- We love using a wort chiller for this, it can get the beer down to temperature in 20-30 minutes. Otherwise, you can immerse the brew pot in an ice bath or wait it out. The longer it takes, the greater the risk of infection

Fermentation -> Turning the wort into beer

- After the boil is done it is time to be extra careful in regard to sanitation. We recommend using a no-rinse sanitizer called Starsan. Mix ¼ tsp of it with water in a 500ml spray bottle. Before we touch any part of the beer we spray it with Starsan.

- Transfer the cooled wort into your fermenting pail or carboy. Run it though a strainer to catch any hop or grain residue.

- It is also an important time to take a hydrometer reading. It should be around 066 give or take a few points.

- Make sure the wort has been cooled to at least 25c!!! Adding yeast at a higher temperature will likely kill it.

- Once the beer is in the fermenter, pour in the 11.5g sachet of S-04 yeast

- Put the bung and airlock in the hole (make sure there is water filled up to the line in the airlock). If using a pail, make sure the lid is sealed tight. Put the pail in a room that is in the range of 17-21°c.

- After 7 days have passed, it is time to add the cacao nibs and the coffee beans. The cacao nibs are included with the recipe, but the coffee beans we have asked for you to source on your own.

- We recommend adding fresh, good quality beans. We used dark roast ones and were very happy with the result. Check out on our many local coffee shops for some good beans!

- The beans and nibs can be tossed in directly, no need to put them in a bag.

- One thing to keep in mind though, when you open the lid there is the chance of oxygen getting into the fermenter. Especially now that the majority of fermentation is complete. We recommend adding 100g of table sugar or dextrose mixed with 100ml of boiling water to the fermenter at the same time as the beans and nibs. The sugar will ferment a bit and will create more CO2 which will keep your beer safe from oxygen. Alternatively, if you have access to CO2, lay a bit of CO2 over the beer after adding the nibs and beans and it will accomplish the same thing.

- Let the beer sit for another 4-5 days, and then prepare for the bottling step. When you are ready to bottle, open the lid and check the specific gravity, it should be between 1.010-1.020. Proceed to the bottling stage.

Bottling -> We’re getting close to Beer Time now.

- Rack the now fermented beer into a bucket.

- At the same time, mix the priming sugar with 300ml of boiling water and add to the beer. Stir it in VERY gently.

- Make sure to check out a priming calculator to verify the correct amount of sugar. Too much sugar and your beer will end up foamy, or even start blowing the caps off! Too little and the beer won’t be fully carbonated.

- Rack the beer into your bottles or growlers. Then, let them sit for 2-3 weeks at room temperature. Chill and enjoy!